Affiliate Disclosure: This post may contain affiliate links. If you make a purchase, we may earn a small commission at no extra cost to you.

Wondering if you can snip your LED strip lights to the exact size you need? LED strips are super flexible, but not all are cut-friendly. The big question remains: Can you cut LED strip lights anywhere?

Yes, you can trim certain LED light strip types to fit. Yet, it’s not a free-for-all cutting situation. You must stick to the cutting guides that come with your strip. If the strip marks where it can be cut safely, you’re good to go. But be warned, some LED strip lights can’t handle a snip.

Key Takeaways

- Not all LED strip lights are made for cutting.

- It’s crucial to cut LED strips at the places marked safe for cutting.

- Don’t cut RGBIC strip lights or LED strips with IC chips.

- It’s vital to measure properly and follow the maker’s cutting instructions.

- For re-connecting cut LED strips, you’ll need the right tools and skills.

Understanding LED Strip Light Cutting Capabilities

Cutting led strip lights isn’t always an option. Not all models are meant to be cut. Before starting an led strip light installation, check if you can cut the lights you have. Especially true for working with flexible led strip lights or led strip lights dimmable.

Types of LED Strips That Can’t Be Cut

One type that’s not cuttable is the led strip light with IC chips. These chips control a small set of lights at a time. This setup lets the strip show various colors. If cut, you might damage the whole set or strip. This also applies to RGBIC strips, which offer more color variety. Cutting them can mess up how they work.

Identifying Designated Cut Points

Knowing where to cut is key for led strip light cutting. Look for specific marks like cut lines or a scissor symbol. These show where it’s safe to cut. Cutting anywhere else might make your lights dim or lose their color regularity.

can you cut led strip lights anywhere

Factors to Consider When Cutting LED Light Strips

Thinking about cutting LED light strips? Make sure to consider a few things. Start by looking for the marked cut points. This ensures you’ll keep the light strip working well. If you cut in the wrong place, the lights might not work right. They could get dim or show weird colors. So, always follow where the manufacturer says to cut to keep the light even and bright.

Maintaining Consistent Lighting After Cutting

When cutting LED strip lights, be careful to follow the cut points. This helps you keep the light looking the same everywhere. Listen to the manufacturer’s instructions on cutting. It prevents problems like sectioning or having parts that look different. By cutting correctly, your LED lights will work smoothly. Your customized led strip lengths will still light up well without any trouble.

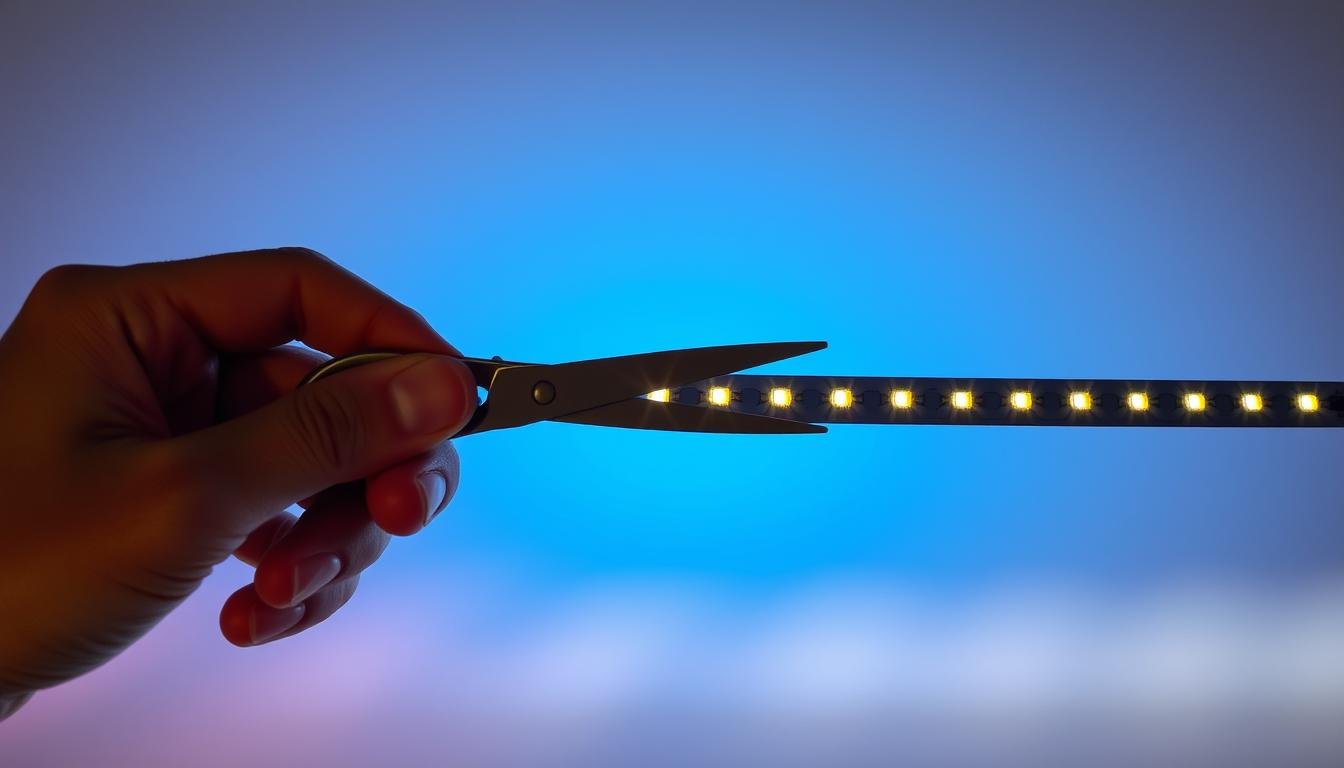

Proper Tools for Cutting LED Strip Lights

Before you cut the LED strip lights, make sure they can be cut. Using the wrong type may damage them. Remember to turn off the power supply first to stay safe. You will need a ruler, a marker, and sharp scissors or a special cutting tool for LED strips. If you will join the cut parts again, you’ll also need a soldering iron and solder.

It’s key to use the right tools for cutting LED strip lights well. Make sure you have everything you need before you start. Always put safety first by turning off the power. This step is vital for a successful and safe cutting job.

Step-by-Step Guide to Cutting LED Light Strips

First, make sure you measure the length of the led strip light accurately. This helps prevent cutting it too short. Look for a marked spot on the strip, like cut lines or a scissor symbol. Use these as a guide to cut.

Measuring the Desired Length

It’s important to measure the led strip lights well before you cut. Use a ruler or tape to get the correct length. Remember, add some space for connectors or power needs.

Following Designated Cut Points

Usually, flexible led strip lights have cut lines or symbols to show you where it’s safe to cut. These points make sure the lights keep working well even after cutting. If you see these marks, cut along them carefully.

Cutting with Scissors or Specialized Tools

For strips with marked cut points, a good pair of scissors is all you need. Cut smoothly, not roughly, to keep it neat. If there are no lines, cut right down the middle to keep the copper even. You can also use special tools for a super-clean cut.

Troubleshooting After Cutting LED Light Strips

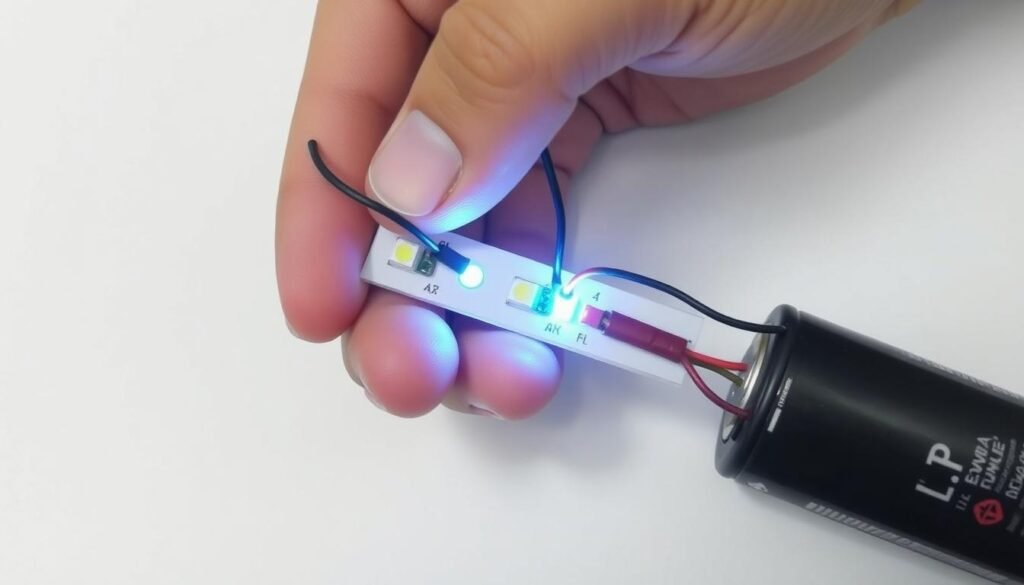

If you cut your led strip lights and now they don’t work, don’t worry. There are ways to fix this. First, double-check that you reconnected the ends correctly. LED strips have a positive (+) and negative (-) side. It’s crucial to match these when putting the strip back together.

Checking Polarity and Connections

Make sure the positive and negative ends of your cut led strip lights match up when you reconnect them. If they don’t, your lights might not turn on. Also, look for any loose or damaged parts when you’re setting up your led strip light installation.

Inspecting for Damage

Take a close look at your flexible led strip lights. Check for cuts, cracks, or burns. If you see any damage, replacing that section is your best bet to keep your lights working well.

Testing Power Supply and Loose Connections

Check that the led strip light power supply gives the right amount of power. Look out for faulty connections in the wiring. Loose connections can stop your lights from turning on or make them work inconsistently.

Reconnecting Cut LED Strip Lights

After you cut your LED light strip, you might want to reconnect it for different reasons. You can make it longer or create turns. The first step in reconnecting is to pick the right connector.

Selecting the Appropriate Connector Type

The main connectors for LED strip lights are four-pin, T, and L-shaped connectors, along with connector wires. It’s crucial to choose the right one depending on your goal. For example, a four-pin connector smoothly joins two cut LED strips. A T-connector is great for making a turn. Use connector wires to make your strip longer, and L-connectors are good for corners.

Inserting and Securing the Cut Ends

After you’ve got the right connector, carefully put and fix the cut LED strip ends in it. Start by removing the insulation to show the copper. Then, place the ends correctly in the connector. Ensure the plus matches with the plus, and the minus with the minus.

If you know how to solder, you can join them that way. This makes the connection stronger. But, you can also connect them without solder. Just be sure they’re firmly attached. This way, the light will flow smoothly, and you won’t have issues.

Creative Applications for Cut LED Strip Lights

LED strip lights are super versatile. You can use them in many creative ways, even after you’ve cut them.

They work great for lighting up staircases. Placed along stair edges, they make stairs look cool and safer. This makes your home look more elegant and cozy.

Accent Lighting for Home and Furniture

LED strips are not just for stairs. You can also use them on headboards, mirrors, and furniture. They change a room’s vibe, making it feel cozy and welcoming.

Smart Home Integration and Customization

Using LED strips with smart home tech takes things up a notch. You can control their color, brightness, and timing from your phone. This means they can match your moods and schedules perfectly.

Decorative Lighting for Events and Parties

Want to jazz up parties and events? Use cut LED strips for cool displays. You can light up everything from backdrops to cars with them. The ideas for their use are endless.

Safety Considerations When Cutting LED Strips

When you’re working with , safety comes first. Always turn off the power before you start to cut. This avoids any electric shocks or harm to the LEDs.

Trying to cut with the power on is dangerous. You might cause a short circuit or touch live wires. Make sure the are off completely before you begin.

Remember, cutting can lead to injury due to sharp edges. Use care and the right tools, such as scissors or a cutter made for this. You might also want to wear gloves to keep your hands safe.

Keep safety as your main focus and refer to the manual when dealing with , , or . This way, you can cut your LED strips without any worries. Always put safety before all else when handling electrical items.

FAQ

Can you cut LED strip lights anywhere?

What types of LED strips can’t be cut?

How do I identify the designated cut points on LED strip lights?

What factors should I consider when cutting LED strip lights?

How can I maintain consistent lighting after cutting LED strip lights?

What should I do if I encounter issues after cutting LED strip lights?

How can I reconnect the cut LED strip lights?

What are some creative applications for cut LED strip lights?

What safety considerations should I keep in mind when cutting LED strip lights?

Check out our FREE Calculators on our Resources Page